As you’ve reached for Aunt Jemima or Mrs Butterworth’s at the grocery store you may have looked up at the top shelf and wondered why those other brands are so expensive.

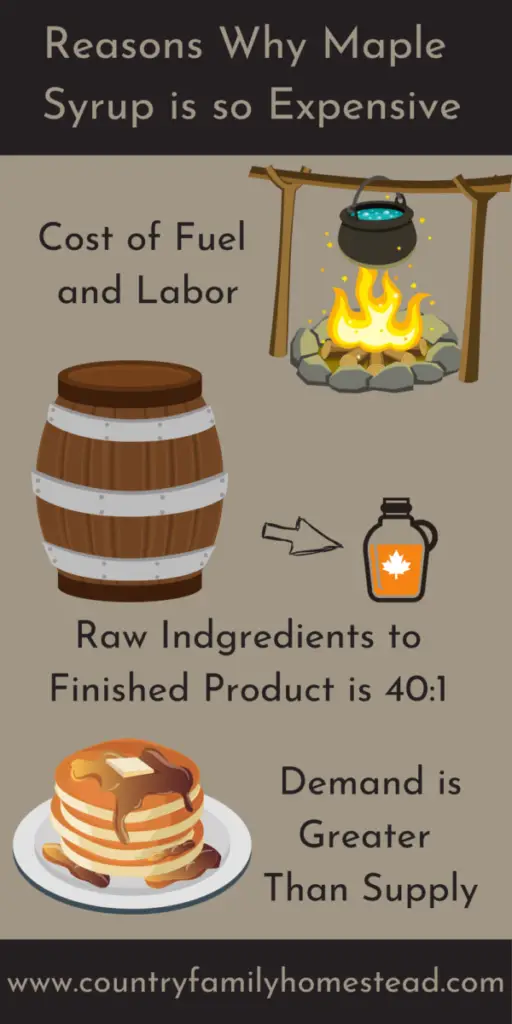

The reasons why pure maple syrup is so expensive and costs 8 to 12 times more than “maple flavored” syrup are threefold: It is a very labor and fuel intensive process, the ratio of raw material to finish product is 40:1, and the supply is limited while demand is high.

The fact is, those well-known commercial brands of pancake syrup are not even maple syrup at all, but typically made from high-fructose corn syrup. Let’s take a look into the process of making pure maple syrup to see why it is so expensive.

Labor and Materials

Maple sugaring (the process of making maple syrup) is often not fully understood by most people. Images of an 80 acre woodlot with a hundred or so galvanized pails hanging on the trees with a flat wooden sled containing barrels of sap pulled by a single horse are what some of us think of. The lane from the forest back to the homestead would lead right to the sugar shack which is a wooden shed with a wood-fired evaporator and a vented roof to let the steam out.

While this is still the process for many small family run operations, there have been many innovations in the maple syrup industry that have increased the output and efficiency of a sugar bush (woodlot of maple trees).

The modern maple sugaring operation will have thousands or even tens of thousands of taps connect to miles and miles of tubing and piping that is connected to a vacuum pump systems to extract the maximum amount of sap and transport it right to the processing facility.

According to the Maple News, the largest maple syrup operation in the United States plans to eventually have 750,000 taps and over 7,000 miles of tubing for their commercial operation. That’s enough tubing to stretch from Vermont to California and back.

Installing all that tubing and setting the taps can take a crew a month or two to accomplish. Sometimes the tubing is left up all year, but usually on leased land the owner doesn’t like to see the miles of blue tubing as he’s out enjoying the forest the remainder of the year, so the terms of the lease usually require the operator to remove the tubing after each season.

If the tubing is left up all year, there is the maintenance to deal with. Critters such as squirrels and chipmunks love to chew on plastic and can cause a lot of damage to a collection system. Deer and other large animals will crash through the tubing causing a lot of rework.

The processing facility needs to be kept clean and sanitized, equipment must be maintained. Then there’s administrative costs such as bookkeeping, ordering, payroll, and advertising. Bottles and boxes must be ordered and received. Labels have to be designed and printed to be affixed to the bottles. The list goes on and on of expenses faced by the modern maple syrup operation.

Evaporation Process

In general, 39 gallons of water would have to be converted to steam and water vapor to produce 1 gallon of syrup. That equates to adding 374,000 BTU’s of heat energy to the sap boiling process to make one gallon of syrup. Using propane as a fuel source would cost about $12-13 for that one gallon. Propane is typically the most expensive fuel used for this, but even using natural gas or wood still adds significant cost to the finished product.

Smaller operations typically use wood burning evaporators utilizing firewood from their own woodlots. This may reduce the cash outlay for the fuel, but still requires a time commitment to cut, haul, stack, and split all that fuel.

Bigger operations that can afford a large investment into the equipment have started using Reverse Osmosis units to remove a percentage of water from the sap to increase the sugar content and speed up the boiling of the sap. These units can cost many thousands of dollars and require extra maintenance costs. For a large operation these costs are far outweighed by the fuel and time savings during the evaporation process.

Rate of evaporation will affect how many man-hours are required to boil all the collected sap into syrup. The evaporation rate is directly related to the surface area of the evaporator and the amount of BTU’s given off from the fire below it. This will vary by the size of the operation, but generally the bigger the operation the bigger the evaporator.

From Sap to Syrup

So far we’ve covered the labor intensive process of setting up the taps and tubing, the high cost of fuel and evaporator & reverse osmosis equipment, and the time required required to reduce the sap from about 2-4% sugar content down to 66% sugar or finished maple syrup.

When the sap is nearing completion it is transferred to what’s called a finishing pan. The operator can monitor the syrup with a hydrometer to get the specific gravity of maple syrup. As the sap starts to thicken into syrup the boiling point also increases from 212 degrees Fahrenheit to about 219.5 degrees for the finished product.

Once the syrup has reached it’s final consistency it must be bottled in sanitized bottles, labels affixed, boxed up and shipped out. Sometimes this is done right in the sugarhouse, but sometimes bulk shipments of barrels of syrup are sent to distributors that bottle for specific brands and distribute to a network from there.

The next item to consider is the grade of the syrup. While Canada and the US previously had similar but separate grading systems, both countries now follow the International Maple Grading System. The lightest color is Grade A Golden Color and is made from the first run of the season. As the season progresses the color becomes darker and the grades go from Amber to Dark to Very Dark.

The price of course also varies by grade with the lightest grade being the most expensive and each step darker being a little less expensive. The darker grades have a stronger flavor and each person has their own specific preferences so a cheaper grade may be more suited to your own taste buds. This Vermont Maple Syrup Sampler from Amazon will allow you to taste three different grades to decide for yourself.

Supply and Demand

A limited supply of maple syrup also attributes to the high cost. There are only so many mature maple woodlots in North America, and the maple sugaring season is only about 2 months long due to the nature of the sap flow. For these reasons and the high cost of entry to a large commercial operation, the supply of maple syrup is limited.

And while the overall production of maple syrup has been increasing over the past few years, the global demand for the product has kept pace. Maple trees and therefore maple sap which is the single raw ingredient for maple syrup is a limited natural resource. A resource that can be affected by weather, wildfire, or invasive species. This makes for a delicate balance between supply and demand.

It’s such a delicate balance that Quebec which produces nearly 70% of all the world’s maple syrup actually keeps barrels of maple syrup in reserve stored in giant warehouses. This helps keep the market stable and levels out any spikes or valleys in the supply and demand.

As the consumer you are basically left with three options:

- Stick to the cheap imitation syrups and never really experience the rich and complex flavors of the real thing

- Fork out a little extra cash and obtain pure maple syrup and accept that for a better product you’ll need to pay a little more.

- Learn to make your own maple syrup from a few maple trees right in your own backyard. Here’s a link to a video playlist that shows exactly how to do just that. Check the resource page for a list of equipment you might need to make it yourself.

For me, I have been making my own maple syrup from the three large maple trees on my property for the last 5 years or so. Once you experience that taste of warm syrup from your very first batch you made yourself, you’ll be hooked forever.