For someone shopping around for their first tractor and are contemplating what size to get or maybe you just picked up a used tractor and you’re wondering what implements will fit my 3-point hitch. Some people wonder “Are all 3-point hitches the same size and can they handle the same weight?”.

There are several different categories of 3-point hitches. For garden tractors, sub-compact tractors and compact tractors, there are probably only two that you’ll need to know about: category 0 and category 1. Larger tractors will have category 2, 3 or 4 hitches depending on the size or horsepower of the tractor.

This article will explain how the 3-point hitch works and break down each category with dimensions, weight capacity, typical implements used with them and also discuss a few variations to the standard 3-point hitch categories.

How a 3-Point Hitch Works

A 3-point hitch is typically permanently mounted to the rear of a tractor. The hitch consists of two lift arms as well as a top link. The lift arms are controlled by the tractor’s hydraulic system to allow for up and down movement of the arms and thus the implement attached to them. The top link keeps the implement in in the same vertical plane as it is raised and lowered. The top link’s length is adjustable to keep the implement level or tilted depending on the need.

On the end of the lift arms and top link are holes that mate with pins on the implements. This allows for easy attachment and removal to quickly change implements on the tractor. For each increasing category of 3-point hitch the holes and pins also increase in diameter. Thus a specific category of implement must be matched up to the size of the 3-point hitch on each individual tractor.

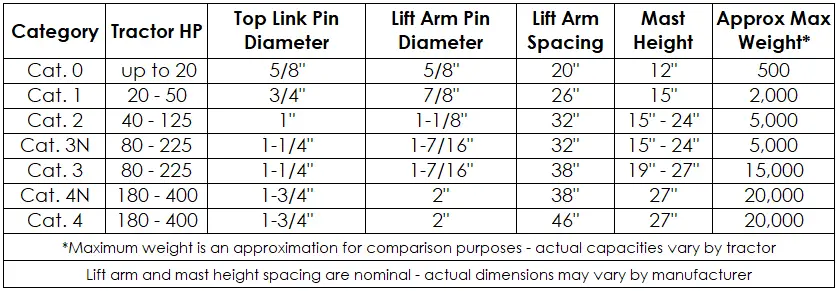

General Dimensions and Capacities of 3 Point Hitches

This table shows some overlap in categories and tractor horsepower and this is because for those size tractors in the overlap range they could have either the lower category or the upper category. For example: a Massey-Ferguson 1750M is a 48 hp tractor with a category 1 hitch while the Massey-Ferguson 2604H is a 45 hp tractor with a category 2 hitch that also converts to a category 1. Here in this example the difference is because the 1750M is considered a compact tractor and the 2604H is considered a utility tractor.

Category 0

Category 0 3-point hitches are almost exclusively found on garden tractors and lawn tractors. They are considered light-duty and accept implements that are 20″ wide. The dimension from the lower pins to the top link pin is typically 12″.

Many manufacturers have made tractors with cat. 0 hitches including Bolens, John Deere, Cub Cadet, Case and many more. The range of implements is quite extensive to include tillers, plows, cultivators, back blades, thatchers, and more. Some implements were specific to the tractor as not all category 0 hitches were standardized and the driven implements had differing methods such as belts/pulleys or driveshafts from a PTO.

A used garden tractor with a category 0 hitch in good shape with several implements will fetch a hefty price. They were pretty popular in the 1970s through 1990s but I don’t know of any new garden tractors with a category 0 hitch. A few were made into this century, but a thorough internet search revealed nothing current.

There are still many different implements available for category 0 hitches. Both used and new. Building or modifying these implements is also a pretty popular project for the home fabricator.

IMPACT Implements makes a rear grading blade, box scraper, landscape rake, and a disc/plow harrow that are lighter in weight and fit the category 0 specs. All those implements including this rear blade can be found on Amazon.com

Some older sub-compact tractors were originally equipped with category 0 hitches like the Sotah Beaver. As time went on though all sub-compacts pretty much came with a category 1. My Bolens G152 is a only 15 hp but has a category 1 hitch. Most new subcompact tractors start at about 20 hp or so and come with a category 1 or a limited category 1 3-point hitch which we’ll cover next.

Category 1

Category 1 hitches are generally found on subcompact and compact tractors from 20 hp up to about 50 hp. The top link pin measures 3/4″ in diameter and the lift arm holes are 7/8″. The spacing between the lift arms is approximately 26″ while the mast height is 15″. The mast height is the vertical dimension between the center of the lift arm pins and the center of the hole where the top link goes.

Not all category 1 implements will be compatible with all tractors with a cat 1 hitch. For example a 6′ category 1 heavy duty rear blade weighs over 300 lbs which might be a little too much for a small subcompact like my Bolens to handle. But a 5′ category 1 rear blade is right around 200 lbs and works great behind my tractor.

The same sort of comparison applies to tillers. My Bolens G152 can handle a medium duty 4′ tiller but nothing bigger or heavier. My father-in-law’s John Deere 2025r can handle a 5′ or 6′ tiller with no trouble. Be sure to consider what the tractor itself is capable of and not just matching up the category size.

Limited Category 1

Some smaller subcompact tractors have what’s referred to as a Limited Category 1 3-point hitch. Limited cat 1 hitches have the same mounting dimensions as a standard category 1 hitch, but the difference is in the tractor and how much ground clearance and lifting arm travel it has. A tractor with a limited cat 1 hitch may not be able to correctly lift some implements to work properly.

Category 2

Starting right around 40 horsepower tractors are equipped with a category 2 hitch. The maximum horsepower for cat. 2 hitches is around 125 hp. These 3-points use 1″ top link pins and 1-1/8″ lift arm pins. The lift arm spacing is 32″.

Category 2 equipment is built much more heavy duty than cat. 1 stuff. There is also fewer used pieces for sale typically. Most of these implements are purchased through dealers and not found at the tractor box stores. Most category 1 implements can be modified for use on cat. 2 either by changing the pins or using bushings to get the right diameter. Some category 2 hitches have interchangeable balls in the end of the lift arms to accept cat. 1 pins.

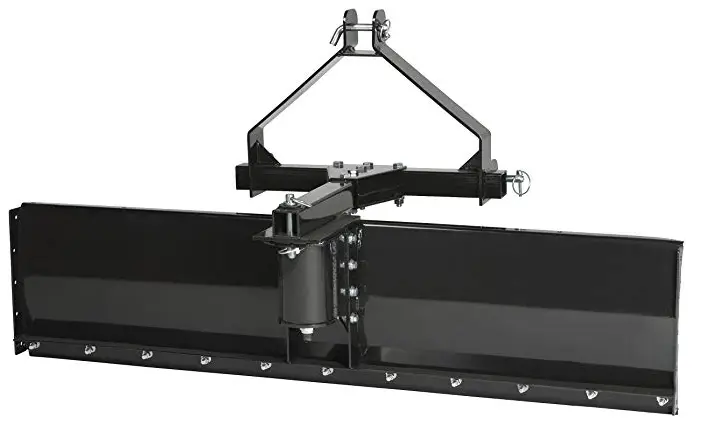

The basic implements such as back blades, box scrapers, and rakes all are made in cat. 2, but are typically much larger and heavily built. A lot of agricultural equipment such as liquid sprayers and planters are usually made for category 2 or larger hitches.

Category 3

Category 3 hitches are found on tractors of 80 hp to 225 hp and have top link pins that measure 1-1/4″ and lift arm pins of 1=7/16″. The spacing of the lift arms is about 38″. There is also a category 3N hitch which has the same pin diameters but the lift spacing is narrower at 32″.

Category 3 tractors are beyond what most homesteaders will have, but if you do be aware of the the difference between the cat. 3 and cat. 3N implements when shopping for one. There are quick hitches available that allow conversion of a cat. 3 hitch to 3N. The 3N being the same width as a category 2 will also accept those implements when bushings are applied to the pins.

Applications for cat. 3 include: medium-sized 3-point hitch implements, such as row-crop cultivators or field cultivators.

Category 4

Category 4 hitches are found on tractors of 180 hp or greater and have top link pins that measure 1-3/4″ and lift arm pins of 2″. The spacing of the lift arms is about 46″. There is also a category 4N hitch which has the same pin diameters but the lift spacing is narrower at 38″.

Quick Hitches

Quick hitch systems mount to the 3-point hitch on a tractor to allow for easy on and off of implements. Many tractor manufacturers make quick hitches specifically for their brand of tractor and attachments such as the John Deere iMatch quick hitch. There are also aftermarket brands of quick hitches that are usually a lot more inexpensive such as this Titan found on Amazon.com.

Quick hitches will usually require bushings be added to the implement to avoid a sloppy fit as the hook size of the quick hitch is larger than the standard pin size. The other issue is that due to the way some implements are made, they may not be compatible with a quick hitch. This usually is because of not enough clearance for the hooks on the hitch. There are adapter brackets available that will allow for attachment in some situations.

One attachment that definitely will not work with a quick hitch is an auger style post hole digger. Check out this video on YouTube to see why this is. When you see the geometry of the post hole digger you’ll see why it won’t work with a quick hitch.

When considering purchasing a quick hitch the best thing to do is take careful measurements of your existing implements you want to use it for and compare to the dimensions of the quick hitch. Once you get familiar with your quick hitch, any new implements you are wanting to buy will only take a quick glance to tell if they will work or not.

Older Variations

Although the 3-point hitch has been around for nearly a century, most antique tractors were not equipped with one. Ford had a lock on the patent for quite some time and farmers with tow-behind implements didn’t necessarily want to invest in all new 3-point implements when the old ones were still in good working condition.

There were some competitors though such as Farmall’s Fast Hitch in both a one-point and two-point version. This system wasn’t introduced until the early 1950s and was specific to International Harvester and their own line of implements. The Super C we have here on the homestead has the Fast Hitch system with a couple of attachments which makes it pretty handy. Our Super C also has a 3-point adapter to all use of many other implements too.

A couple other tractor brands also had their own proprietary attachment systems. Allis Chalmers made the Snap Coupler system and Case had the Eagle Claw hitch. You still see these systems in use on the old tractors. All these old style hitches have their pros and cons, but what really signaled their demise was the fact the 3-point patent ran out which allowed many tractor manufacturers to adopt it and the bulk of implements that were available for it.