A tractor without implements is like a drill without drill bits. It might be cool to look at and play around with, but you can’t really get any work done. 3-Point implements are like drill bits, they allow the tractor to become the most useful tool on the homestead.

There are so many different implements that are available for your tractor that I’ve compiled a list below of the most useful ones but that are still affordable. This list includes implements with a starting price of $1000 or less. Sometimes way less. I’ll break down what each is used for to help you decide if it fits your needs. Let’s start with the least expensive and work our way up.

Drawbar Hitch Receiver

Drawbar hitch receivers mount to the 3-point hitch on a tractor to easily allow the insertion of a 2″ trailer hitch for moving and hauling trailers around the farm or homestead.

If you have a quick hitch it’s important to make sure the drawbar hitch receiver is compatible with it. The way to tell is that there is enough room for the top hook of the quick hitch to slide under the top link pin. This is true for any 3-point implements. The drawbar pictured above is an example of one that is compatible from Titan which has great reviews and can be found on Amazon.com. Quick hitch bushings will also be needed to slip over the pins to eliminate any slop.

Drawbar hitches start in price around $60 or so and go up from there to about $300. The cheaper ones are probably going to be made in China and be lighter duty. There are some features that increase the price such as a ball on the top of the hitch or holes for accepting bale spears. Heavy Hitch has a very heavy duty drawbar hitch that is made from American steel and also accepts suitcase weights and pallet forks to make it very versatile.

Rear Pallet Forks

Rear pallet forks may be your only option to move pallets of material or lengths of logs if you don’t have a FEL (front end loader) on your tractor. The forks pictured here are from Titan and can be found on Amazon.com

It’s important to note that these 3-point pallet forks may have a heavy duty weight rating, but a small tractor without any weight up front may not be able to lift more than 400-500 lbs. Keeping the load as close to the tractor as possible will help keep it stable. Some of the lighter built forks are much shorter to keep from getting the center of gravity too far out on a small tractor.

Some of the 3-point pallet forks have fixed width forks while some are adjustable, so be sure to match up the width with what you need to move. We have a set of pallet forks here on the homestead that is usually mounted to the Super C which holds the carry-all box for hauling firewood and also for moving the vegetable stand out to the road during harvest.

3-Point rear pallet forks will start around only $140 or so. These are much lighter duty with shorter forks but for smaller tractors usually are just about right. Once you get into the more heavy duty ones the price could run up to $400 or more.

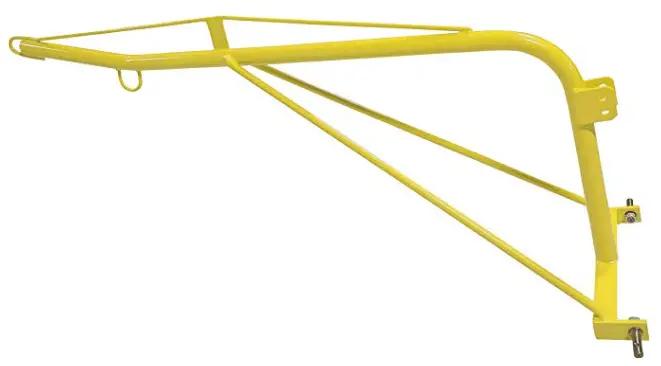

Boom Pole

The 3-point boom pole is very handy for moving equipment around the homestead, loading or unloading trucks or trailers, and for skidding logs out of the woods.

This one pictured above has a weight capacity of 1000 lbs. on the close hoop and 500 lbs. on the far hoop. Titan makes some very good quality tractor implements and accessories and this is no exception. This boom pole is at Amazon.com and has many great reviews and I actually plan on buying this one in the near future.

Not overloading a boom pole is similar to the rear pallet forks. The smaller the tractor the less weight you’ll likely be able to lift. This is not only because the hydraulics on a smaller hp tractor can’t lift as much, but also because of the lack of weight in the front end of the tractor. Placing suitcase weights on the front will definitely help if the tractor is designed to carry them. Getting too much weight out on the end of the boom can be a dangerous situation if the tractor were to tip over.

The other precaution I’d like to mention is to try and minimize the swing of the item you lift. Keep the tractor speed to a minimum also as a quick turn with a heavy load on the end can cause the tractor to rollover. The weight of the load is following the rules of Newton, an object in motion tends to stay in motion. To minimize swing, shorten the chain or strap, attach as close to the tractor as possible, and fasten a rope to the load with a helper standing off to the side to keep the load under control.

Boom Poles range in price from $160 to $300 or more. The price is usually determined by the quality and weight capacity. It helps knowing what your tractor can lift and what your intended load will be to get the most value for you money.

Middle Buster

Middle Busters are a handy tool for someone with a large garden or the need to do some trenching or ditching to drain water. This Titan middle buster can be found on Amazon.com/

This tool is especially useful for the potato gardener. It will dig a nice furrow for planting in the spring and then when the potatoes are ready for harvest, you run the middle buster down deep through the row and the potatoes roll right out. It really saves the back by not having to dig them up with a shovel or pitchfork. This YouTube video from HOSS-IT-IS shows how this same model middle buster does a great job of harvesting potatoes.

A middle buster can also be used to trench a ditch for diverting water or even as a good start to a trench for electrical or water lines. It may only get you 10-12″ deep but by ripping the sod off and breaking up some of the subsoil it will make hand digging the rest of the trench much easier.

Middle busters start at around $150 and go up to $400 or so. The price all depends on how heavy duty it is made. Most of the ones you find for sale at the tractor box stores or online are right around $200 for a pretty decent one.

Subsoiler

Subsoilers are use to break up compacted soil from heavy livestock or vehicle use. They come in a single shank for smaller compact tractors and multiple shanks for larger hp tractors. This one from Amazon.com fits category 1 hitches but not quick hitches.

A single shank subsoiler can also be modified to use as a wire or pipe trencher too. Some manufacturers offer attachments for this, but many tractor owners make their own modifications to perform this task. Here’s a link to a good YouTube video from Country View Acres showing how well this works.

One thing to keep in mind is that some of these subsoilers are one solid welded piece. If you hit an immovable object underground with a smaller hp tractor it will most likely just stop the tractor in it’s tracks without causing any damage. But on a larger tractor, the tractor will have enough power to want to keep going and possibly cause damage to the implement, hitch or tractor itself. The way to avoid this damage is to use a subsoiler with shear bolts that will break and allow the shank to swing free of the obstacle. Depending on the type soil in your area, you may want to keep extra shear bolts handy.

Single shank subsoilers start at $200 and go up from there to about $600 for a very heavy duty one. There are single rippers that insert into your drawbar hitch receiver for less than $100 but they don’t dig as deep as a subsoiler.

Landscape Rake

A 3-point landscape rake works by digging into the top few inches of soil to pull up any stones, sticks, roots or trash while allowing the dirt to sift back through the curved tines. The tines have some spring action to them to allow them to flex over uneven terrain.

Landscape rakes are also useful for leveling and grading soil for planting preparation. I used one when I built my house to do the final grading after the bulldozer finished the rough grade. In fact the landscape rake has many different uses such as:

- Gravel drive maintenance

- Finish grading

- Removing stones and debris from soil

- Breaking up old sod for replanting

- Food plot preparation

- Leveling freshly delivered topsoil

- Beach grooming

Landscape rakes come in many different sizes and price ranges. You can find a few category 0 rakes that are 3′ or 4′ in length. Category 1 landscape rakes start at 4′ and go as wide as 8′. The rake pictured above is a category 1 5′ model from Amazon.com. Prices start around $300 and go up to about $750 depending on the length and how heavy-duty it is built.

One option to consider for your landscape rake is a gauge wheel kit. The wheels allow you to control your rake depth to keep the rake from digging down to far over uneven terrain. Replacement tines are also available should you happen to break one.

Cultivator

Cultivators have two main purposes: preparing the soil for planting crops in the spring and keeping the rows between crops weed-free during the growing season. In the spring the cultivator will mix up the soil along with any organic material that was left to decompose over winter. This also helps to aerate the soil and increases the soil temp quicker by mixing in the top layer that has been warmed by the sun and exposes new fresh dirt to the surface.

Category 1 cultivators come in different widths to cultivate either one, two or even three rows at a time. The tines are adjustable and removable to accommodate your specific needs. This cultivator from Amazon.com is 5′ wide with 11 tines and gauge wheels that allow for 3″-6″ of consistent depth.

Some other options in addition to gauge wheels is a removable center furrow blade to make quick work of seed planting and hillers to push the soil back up to the center to cover seeds and for hilling potatoes.

Cultivators run from about $300-$900 depending on the width, number of tines, and accessories with it. Used cultivators are also pretty easy to come by for less than $200. Here on the Country Family Homestead we use an old cultivator on the Farmall Super A. The Super A has plenty of clearance to cultivate corn even into July. Once crops get much taller than knee high the shade from them usually prevents too many weeds from sprouting.

In this video from our YouTube channel we show you some of the different used implements you can find and the cultivator we ended up getting and how it worked for us.

Back Blade

The 3-point back blade is probably the most popular implement for tractor owners. This is because it is so darn handy and versatile. This 6′ medium-duty blade has good reviews on Amazon.com.

3-point back blades come in sizes from 4′ up to 7′ or 8′ for category 1 hitches. There are larger and more heavy-duty blades available for larger tractors, but will require a category 2 or 4 hitch. We have a couple of them here on the homestead. There’s a 5′ blade on the Bolens subcompact that pretty much stays on most of the time and a 7′ blade that typically goes on the Farmall Super C for snow removal. There are so many uses for 3-point back blades that I compiled a list below:

- Snow removal

- Driveway maintenance

- Road building

- Spreading dirt, sand, or gravel

- Cleaning livestock pens

- Ditch work

- Scraping topsoil

- Clearing small trees and brush

Standard back blades typically will have a full 360 degrees of rotation to allow for pushing or pulling or angling to one side or the other. Some higher-end models have options for hydraulic controlled blade angle and tilt. Other options for back blades include gauge wheels and skid plates to help with depth control.

3-point back blades start at about $300 for a smaller light-duty category 0 or 1 blade and go up to around $1200 for an 8′ heavy-duty category 1 blade. The cost can go way up from there for the larger blades with hydraulics or other options.

There are several videos of tractors using back blades on our YouTube channel. Check out the playlist here.

Box Scraper

The 3-point box scraper or box blade as it is sometimes called is a great tool for anyone with a long gravel driveway or road to maintain. They work similar to a back blade but with a few extra features. There are adjustable scarifiers that help break up the soil and the sides of the box blade allow excess soil to build up to fill in low spots and leave a smooth path behind the implement.

Not only do box scrapers work great for road maintenance but are also really good for finish grading of yards, light-duty ripping, and back-filling. The 4′ box scraper pictured above has good reviews on Amazon.com. Widths go from 4′ to 8′ in 1 foot increments with the price starting at about $500 up to over $1000 depending on the size.

Post Hole Auger

3-point post hole diggers have a PTO driven gear box that drives an auger bit for digging holes. Typical sizes bits are 6″, 9″, 12″ or 18″ in diameter that are usually from 32″ to 48″ long.

Post hole digger tractor attachments mount to the rear 3-point hitch in most cases although front bucket mounted units that are hydraulically driven are also available. The advantage of the front mounted units is that you can get more down-force from the FEL. The rear mounted ones rely on the drill point of the auger to pull itself into the ground. On most loose soils this usually isn’t a problem though. I borrowed the one the picture to dig 12″ holes for the posts of my barn and didn’t have any issues with getting the auger started. You can watch that video on YouTube.

Compact tractor post hole diggers are a little shorter than the standard ones, and use the shorter 30-36″ long augers. This is because the smaller tractors sit lower to the ground and are not able to lift the auger bits high enough to drive around without dragging. Everything Attachments.com does have a post hole digger that comes with a 48″ bit for compact tractors so that would be a good resource to check out if you have a smaller tractor.

Post hole diggers start around $500 for a basic one on Amazon.com, but that doesn’t usually come with the auger bit. Each auger bit runs between $100-$200 depending on the diameter and length. A nice USA made 3-point auger that comes with one bit can be had for just under $1000.

Spreader

3-Point broadcast spreaders are useful for spreading fertilizer, pelletized lime, seed, and salt. The rotary action of the spreading disc is driven by the tractor’s PTO. The span of spread is determined by the PTO’s RPM and the flow of material is controlled by a gate attached to a lever that the operator can adjust.

This type of broadcast spreader doesn’t have very precise control so it does take some getting used to in order not to spread too much or too little material. The hoppers can be made of steel or plastic and the spreader disc is made of plastic, steel or stainless steel. If you intend to use the spreader for salting parking lots or drives than you would want to opt for the plastic hopper/stainless disc type.

A fertilizer spreader for a compact tractor would be an awesome tool for those making wildlife food plots for fertilizing, liming, and spreading seed. They do not work well with powdered lime as it will tend to clump in the hopper, especially if wet or damp.

With 3-point tractor broadcast spreaders costing between $500-$1000 depending on size and construction, it’s a good idea to keep them clean and well-maintained after use. If the hopper is not empty and you plan on using it again within a day or two, keep it protected from the weather by parking indoors or using a hopper cover. When you are ready for longer term storage use this checklist to ensure your spreader has many years of service:

- Empty hopper completely.

- Use an air nozzle to blow away any leftover residue from hopper and spreader area.

- Use a pressure washer with a mild detergent to clean the spreader inside and out.

- Allow to dry completely.

- Perform any maintenance and lubrication according to the manufacturer’s recommendations.

- Cover and store where protected from the elements.

Disc Harrow

A disc harrow or sometimes just called a 3-point disc consists of a steel frame that supports steel discs that chop and break up the soil as it’s pulled through a field.

The old style disc harrows were mostly tow-behinds, but today’s 3-point discs are made to be lifted with the tractor’s hitch for easy transport. Disc harrows for compact and utility tractors come in sizes from 4′ – 6′. Much larger units are available for large farm operations.

Smaller type disc harrows are great for large gardens or wildlife food plots as they are able to break up sod and mix vegetation debris into the topsoil. The concave dish shape to the the discs and the way they are set on an angle makes the soil lift and mix as it’s drug through the field. This leaves a nicely prepared bed for planting.

3-point disc harrows like the one pictured from Amazon.com start around $900 for a small category 1 disc and go up quickly from there for the larger units. There are also 4′ lightweight models for category 0 tractors for a little bit less.

Brush Hog (Rotary Cutter)

3-point rotary cutters are commonly called brush hogs or even Bush Hogs (brand name). Brush hogs are used to cut heavy weeds, grass, brush and even small trees up to a couple inches in diameter depending on the model and the tractor hp driving it. They are especially useful over rough terrain.

3-point rotary cutters take a little research to get the right one for your application. The PTO speed and hp of your tractor, the width of you tractor and the size of the brush you want to cut must all be taken into account when selecting a rotary cutter. The tractor must be able to power the implement and also to cover the entire width of the tractor to get a nice uniform cut. Let’s go through an example for a John Deere 2036R Compact Utility Tractor:

- Determine PTO speed and hp of the tractor. If you don’t have this information, TractorData.com is a great resource. For the JD 2036R the PTO is rated at 30 hp and 540 RPM.

- Measure the width of your tractor (Tractor Data.com also lists these dimensions if you are looking to purchase a tractor). For our example the John Deere measures 68″ wide.

- Walk the land you want to maintain and look for the largest brush and trees you will need to cut. Let’s say we’ve got poplar saplings up to 1″ in diameter growing in the trails through the wood lot.

- Visit the website for the brand you are considering. Let’s look at the Bush Hog brand at bushhog.com to review the specifications of their rotary cutters. We are looking for a rotary cutter that is at least 6′ wide to cut up to 1″ with a 30 hp PTO. The BH6 model fits all those criteria for our application.

Brush hogs start at just over $1000 which is quite a significant investment. The brush hog is probably the most abused piece of equipment you will own too due to the possibility of hitting rocks, stumps, and trying to cut larger brush than you should. For this reason it pays off to purchase as heavy-duty well-made implement as you can afford.

Finish Mower

A 3-point finish mower is a mower deck similar to what’s under your lawn tractor only it is towed behind the tractor and driven by the tractor’s PTO. A lot of compact tractors have belly mount mowers available for them but the disadvantage is they can be somewhat difficult to put on and take off. If you are using your tractor for many different things and don’t want the belly mower getting in the way than a 3-point finish mower might be a better solution.

The other thing to consider too is whether you should get a brush hog or a finish mower. If there is no shrubs or brush to contend with in the space you wish to keep mowed than a finish mower may be a better option as long as the land is somewhat smooth.

Choosing a finish mower is similar to the brush hog example above where we need to match the tractor’s PTO speed and horsepower to the finish mower we’re considering. The finish mower should also be wider than the tractor for a nice finished cut. Finish mowers typically require less hp for the same width brush hog so for your particular tractor you may be able to get a wider finish mower than you could get a brush hog.

Finish mowers cost around $1000-$2000 for a new one, but used ones can usually be found for around $400-$500 or so for one in decent shape.